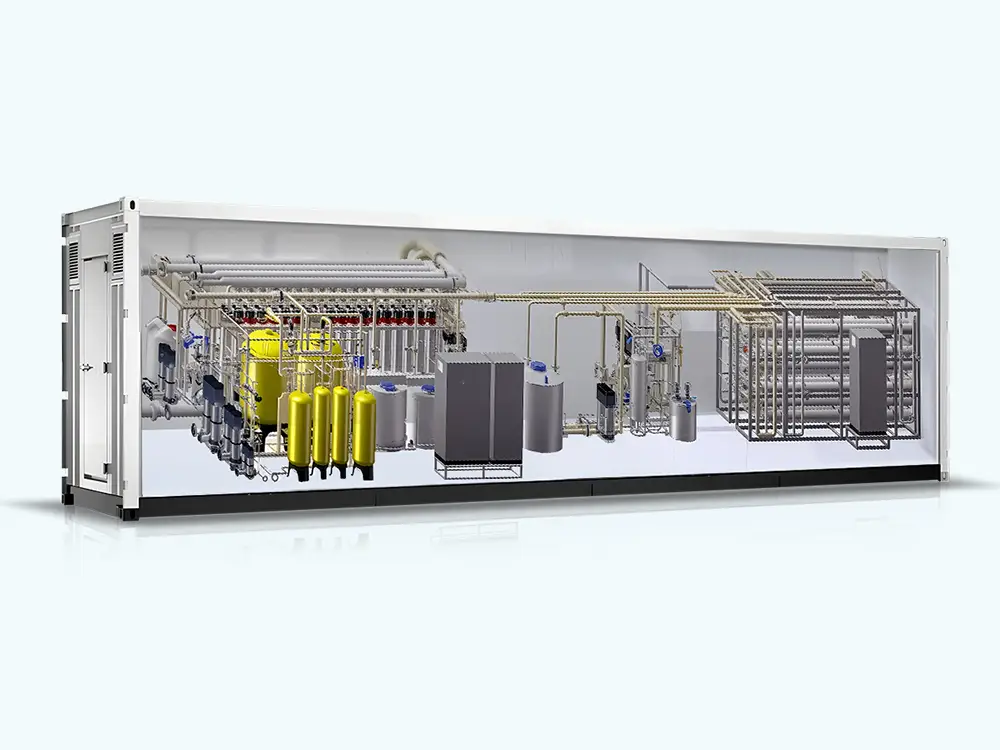

Containerized Boiler Water Softening System

Design Philosophy & Core Advantages

The system adheres to the design concepts of "integration, intelligence, reliability and environmental protection", integrating multiple advanced water treatment processes into a standard container. The core design advantages are as follows:

Designed Raw Water & Treated Water Quality Parameters

| Parameter Item | Specification |

| Treatment Capacity | 5-50 m³/h (customizable according to requirements) |

| Raw Water Turbidity | ≤ 100 NTU |

| Raw Water Hardness | ≤ 100 mg/L |

| Product Water Hardness | ≤ 2.0mg/l/L |

| Product Water SDI | ≤ 1 |

| Container Specification | 20ft/40ft standard shipping container |

| Power Supply | 380V/50Hz (customizable for international standards) |

| Operation Mode | Automatic |

| (With manual backup) |

Note: The above parameters are based on conventional design using surface water as the raw water source. For special raw water (e.g., high fluoride, high arsenic, brackish water, etc.), additional processes (such as RO Reverse Osmosis, Ion Exchange, etc.) will be equipped. The finished water quality can meet the "Standards for Drinking Water Quality" (GB 5749-2022) or even higher standards.

Detailed Introduction of Filtration & Treatment Processes

The Containerized Boiler Water Softening System is composed of five core process sections: Pretreatment System, Nanofiltration (NF) Membrane System, Ultrafiltration (UF) Membrane System, Ion Exchange System and Electrical Control System. The processes are closely connected and complement each other to ensure the final water quality meets the boiler feed water requirements.

Pretreatment System

The pretreatment system is the first line of defense for the entire water treatment process, mainly responsible for removing large particles of suspended solids, colloids, turbidity, organic matter and residual chlorine in raw water, protecting the subsequent membrane systems and ion exchange resins from pollution and damage. The system mainly includes:

Application Scenarios

After-Sales Service

We provide a full set of after-sales service for the Containerized Boiler Water Softening System, including on-site installation and commissioning, operator training, regular maintenance, spare parts supply and technical support. Our professional after-sales team responds quickly to ensure that the system operates stably for a long time.

Do You Have any Questions? Welcome to Leave Us a Message.

Tel: +86 13370035529

Business What's App: +86 13636655908

E-mail: qilee@qileegroup.com

Add: No. 351 Wenqu Road, Fengxian District, Shanghai